Diaphragm Engineering and Design Services

Diaphragm Design

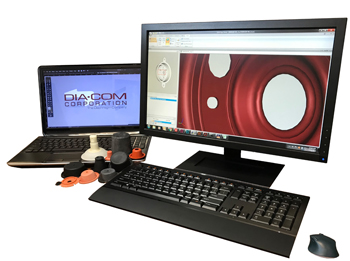

DiaCom Design Engineers routinely work with our customer engineering personnel to transform application concepts first into fully functioning prototypes and ultimately, into production units. Our experience and background allow us to cost-effectively provide a molded rubber diaphragm that meets or exceeds all customer expectations. Computer Aided Drafting enhances DiaCom's abilities to provide accurate customer tooling designs on a timely basis. DiaCom Corporation's application engineers routinely assist customers in the design of standard and specialty diaphragms using state-of-the-art 3-D Modeling software. We are able to accept and utilize most popular formats of these CAD drawings including Solid Edge, STEP, IGES, DXF and others.

Existing diaphragm applications sometimes do not perform as well as intended. Our technical staff is available as an aid to our customers to analyze performance issues, offer hardware recommendations, and to assist in root cause analysis and the implementation of permanent corrective actions.

To speak with a sales or project engineer about your diaphragm requirements, please view, fill out, and submit our Application Data Form .

DiaCom has developed a Diaphragm Design Guidebook that can be used to assist engineers in the basics of diaphragm design. Our Diaphragm Design Guidebook is a complete, hard-copy description of diaphragm theory, diaphragm design, basic materials properties, hardware recommendations and standard tooling lists. The Diaphragm Design Guidebook is available at no charge and can be found here: http://www.diacom.com/pdf/DiaCom-Design-Guidebook-rev4v9.pdf.

Diaphragm Materials Lab

Constantly striving to improve existing applications, meet the demands of new programs, and troubleshoot application issues, DiaCom has established a Rubber Materials Lab that gives us significant rubber-testing capabilities.

Using ASTM standard procedures, we are able to obtain measure physical properties, such as, tensile strength, elongation, modulus, durometer, tear strength, compression set, and rheology data, such as, viscosity, cure times, scorch data, etc.

We are also capable of running a variety of chemical compatibility testing, heat aging, volume swells, etc. using ASTM standard testing procedures, and we can run customer-specific tests.

Part of our Materials Lab is a 16"(406 mm) 2-roll mill that gives us an in-house mixing capability that allows us to deliver new, custom rubber compound formulations. Combining this test capability with our technical expertise allows us to provide materials that meet customer specifications, ASTM material call-out and other certification bodies, such as UL or NSF.

For Product Inquiries & Information Only: